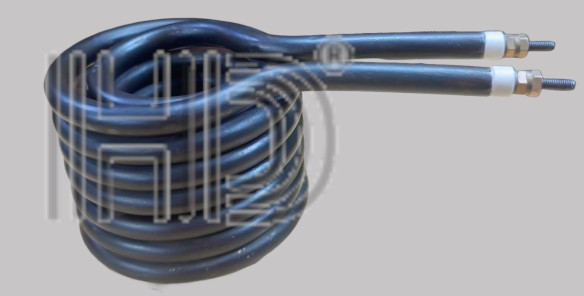

Double Immersion Heater – High-Performance Dual Heating Solution

Our Double Immersion Heater is a powerful and versatile heating device, engineered for fast and efficient heat transfer in industrial, commercial, and domestic applications. Designed with two separate heating elements, it offers greater heating capacity, faster heating times, and built-in redundancy—ensuring uninterrupted performance even if one element fails.

Made from premium Incoloy or SS 304/316 stainless steel, and equipped with nickel-chromium heating elements, it is built to withstand high operating temperatures up to 500°C. A hexagonal, square, or round flange ensures secure mounting, while high-grade magnesium oxide insulation ensures excellent heat transfer and long service life.

Compact, durable, and easy to maintain—the Double Immersion Heater is the perfect choice for heating water, oils, chemicals, and other liquids in tanks, boilers, and industrial systems.

Key Features

- Dual Heating Elements – Operate independently or together for flexible heat control.

- Fast & Efficient Heating – Shorter heat-up times and higher temperature capacity.

- Durable Build – Premium stainless steel or Incoloy construction.

- High Capacity – Ideal for large volume heating.

- Easy Installation & Maintenance – Flange options for quick fitting.

Applications of Double Immersion Heater

- Industrial storage tanks

- Boilers and water heating systems

- Plastic and chemical processing plants

- Oil heating systems

- Food & beverage manufacturing

- Large-scale commercial heating setups

- Papper Cup Machine

Product Specifications

| Specification | Details |

|---|---|

| Product Type | Double Immersion Heater |

| Heater Material | Incoloy / SS 304 / SS 316 |

| Heating Element | Nickel-Chromium Wire |

| Sheath Material | Mild Steel / Stainless Steel / Incoloy |

| Voltage Range | As per requirement (typically 220V–440V) |

| Power Rating | Custom as per capacity (high watt density option) |

| Temperature Capacity | Up to 500°C |

| Flange Type | Hexagonal / Square / Round |

| Insulation | Magnesium Oxide (MgO) |

| Installation | Flange-mounted |

| Applications | Industrial, commercial, domestic liquid heating |

Why Choose Our Double Immersion Heaters?

- Increased heat capacity with dual-element design.

- Energy efficiency with independent element operation.

- Long service life due to premium corrosion-resistant materials.

- Flexible mounting options for different tank and boiler designs.

FAQ – Double Immersion Heater

Q1: What is a Double Immersion Heater?

A Double Immersion Heater is a heating device with two independent heating elements, designed to provide flexible, powerful, and reliable heating for liquids.

Q2: How is it different from a single immersion heater?

It has two heating elements compared to one in single immersion heaters, allowing for faster heating, larger volume heating, and redundancy in case one element fails.

Q3: What materials are used in Double Immersion Heaters?

They are commonly made from stainless steel (SS 304/316) or Incoloy, with nickel-chromium heating coils and magnesium oxide insulation.

Q4: Where can Double Immersion Heaters be used?

They are suitable for industrial tanks, boilers, oil systems, chemical processing, and large-scale water heating.

Q5: Can I control each element separately?

Yes, each heating element can be operated independently or together, depending on the application’s heating requirements.