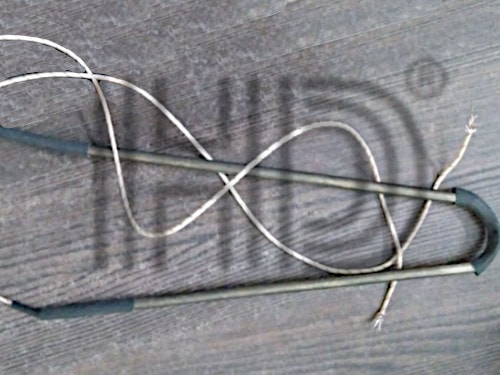

Heating elements known as cartridge heaters are frequently employed in industrial applications to deliver focused heat. They are constructed up of a heating element inside a cylindrical metal tube or cartridge that is often made of stainless steel. A coil of high-resistance wire, such as nichrome, or ceramic insulators are frequently used as the heating element.

In order to transfer heat directly, cartridge heaters are made to be inserted into a hole or hollow in a solid material, such metal or plastic. They are frequently employed in operations like plastic injection moulding, hot runner systems, packaging machinery, and numerous heating applications where precise and controlled heating is necessary.

Features:

- Construction: Metal sheaths are typically used to encase cartridge heaters, which offers mechanical protection and improves heat transfer. Although brass or incoloy can also be used, stainless steel is the most common material used for the sheath. To ensure effective heat transfer, the heating element is securely coiled inside the cartridge.

- Cartridge heaters are available in a range of power and voltage levels to meet the needs of varied applications. The voltage rating ranges from low voltages (like 12V) to higher voltages (like 240V), while the power rating is commonly expressed in watts. It’s crucial to choose a cartridge heater that adheres to the specifications of your particular application.

- Temperature Range: Depending on the materials used in their construction, cartridge heaters can typically run at high temperatures. Depending on the design and application requirements, they have a temperature range from a few hundred degrees Celsius to over a thousand degrees Celsius.

- Options for Mounting: Screw-in holes, flanges, or clamping mechanisms are just a few of the mounting options available for cartridge heaters. The mounting method is determined by the particular application and the need for quick installation and removal.

- Cartridge heaters can be controlled with thermostats or temperature controllers to maintain precise temperature settings. To avoid overheating or damage in the event of any failures, it’s crucial to include safety measures such as fuses, temperature limiters, or thermal cut-off devices.

Cartridge heaters offer accurate and effective heating, which is one of their benefits. For many industrial operations, it is crucial that they be able to maintain a constant temperature and produce even heat dispersion. Without requiring external controllers or power sources, they are extremely simple to install and maintain.

For a variety of industrial and commercial applications, cartridge heaters provide an efficient and dependable heating option.