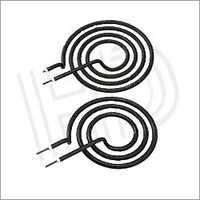

Coil Type Heaters offer a wide range of applications in numerous sectors based on its design and heating mechanism. These heaters are utilised for nozzle heating in injection moulding units. These heating solutions are employed in packaging plants to warm up cutting bars and manifolds. We provide these heaters with a variety of heating ring height, power, and voltage level options. Lead or nickel-chrome-plated wire with a fixed length is used in coil type heaters. These can be accessed with or without a thermocouple of the K or K type. These heaters’ annealed surfaces aid in increasing their malleability. These coil-type heating elements operate at a given temperature both continuously and intermittently. The most important characteristics of these heating solutions are their excellent heating performance and common safety features.

The tremendous heat output and quick response times of coil type heaters are well recognised. They can quickly attain high temperatures and deliver even heating across the coil. The coil may be integrated into a variety of heating systems and pieces of equipment due to its small size and versatility.

These heaters are frequently used in industrial operations like extrusion, hot stamping, food processing, plastic moulding, packaging machines, and many more activities. They can also be found in home equipment including electric stoves, ovens, and hair dryers.

Depending on the needs of the application, a coil type heater’s design and characteristics can change. To guarantee effective heat transfer, electrical safety, and durability, factors including coil diameter, length, wire gauge, and insulation material are taken into account.

Despite the fact that coil type heaters are frequently utilised, alternative electric heating elements such tubular heaters, cartridge heaters, and ceramic heaters are also an option. Based on elements like temperature range, watt density, and physical limitations, each type has unique characteristics and is ideal for particular applications.