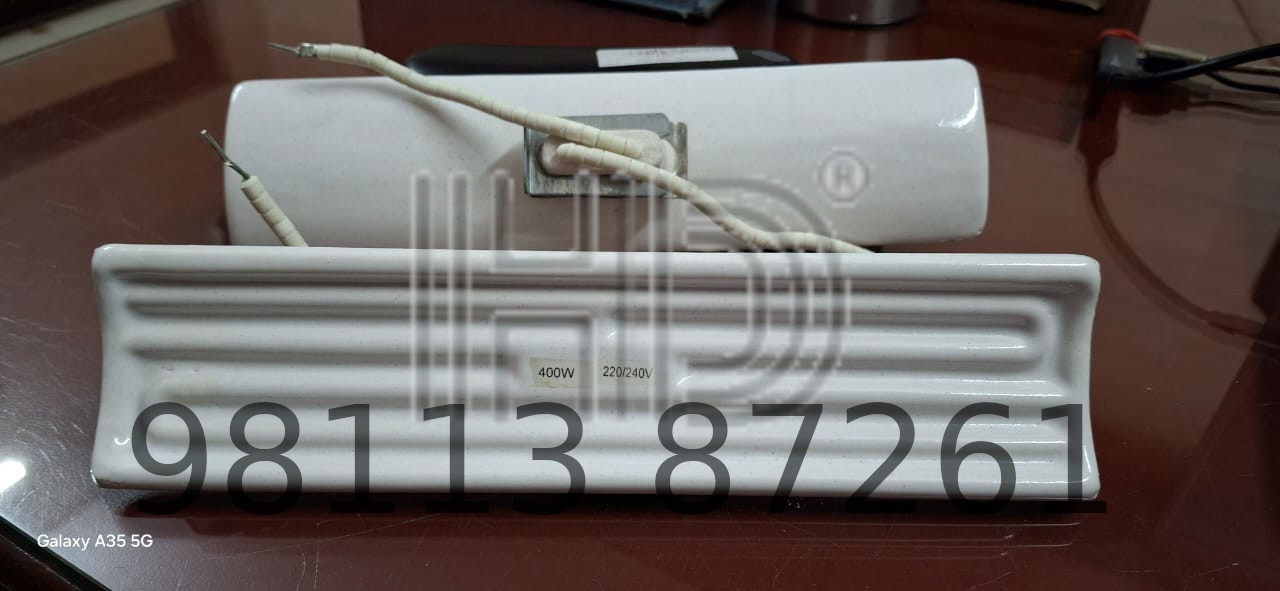

Ceramic IR Heater – Efficient Infrared Heating for Industrial Applications

As a leading manufacturer and exporter of Ceramic IR Heaters, our company provides advanced heating solutions tailored for industries that need energy-efficient and reliable infrared heating. Over the years, we have built a reputation for designing and supplying heaters that combine cutting-edge technology, durability, and precision heating performance.

A Ceramic IR Heater (Ceramic Infrared Heater) works on the principle of infrared radiation, a highly efficient method of transferring heat. Unlike convection heaters that warm the surrounding air, Ceramic IR Heaters emit infrared waves, which are directly absorbed by objects and surfaces. This makes them incredibly effective for applications where fast heat-up times, focused heating, and uniform temperature control are critical.

Understanding Ceramic IR Heating Technology

Ceramic IR Heaters typically operate in the 2–10 micron wavelength range, which falls in the medium and far-infrared spectrum. This range is ideal for heating because materials and objects naturally absorb these wavelengths efficiently, ensuring better heat penetration and energy savings.

- Near Infrared (0.78 – 2 microns): Shorter wavelength, intense heat, used for applications needing rapid surface heating.

- Medium Infrared (2 – 4 microns): Balanced heating, suitable for plastics, curing, and packaging processes.

- Far Infrared (4 – 10 microns): Gentle, deep heating ideal for drying, food processing, and surface warming applications.

The wavelength and heating power of a Ceramic IR Heater depend on factors such as its design, material composition, and operating temperature. Our heaters are designed to match the specific needs of industries, ensuring consistent performance.

Key Features of Ceramic IR Heaters

- High Energy Efficiency – Direct heat transfer reduces heat loss and lowers energy costs.

- Fast Heat Response – Rapid heat-up and cool-down times improve production efficiency.

- Uniform Heat Distribution – Ensures even heating with no hot or cold spots.

- Durability – Ceramic construction withstands high operating temperatures and mechanical stress.

- Low Maintenance – Long service life with minimal upkeep required.

- Customizable Design – Available in various shapes, sizes, wattages, and voltage ranges.

Applications of Ceramic IR Heaters

Our Ceramic IR Heaters are widely used across industries for:

- Plastics Industry: Pre-heating, thermoforming, injection molding, and blow molding.

- Packaging Industry: Shrinking, sealing, and lamination.

- Textile Industry: Heat-setting and drying fabrics.

- Food & Beverage: Infrared baking, drying, and warming processes.

- Paint & Coatings: Curing, drying, and surface finishing.

- Electronics: Controlled heating for PCB drying and component processing.

By using Ceramic IR Heaters, industries benefit from reduced energy usage, faster processing times, and improved product quality.

Our Manufacturing Expertise

Since our establishment, we have consistently invested in world-class technology and quality control systems to deliver products that exceed international standards. Our expertise spans a wide range of heating solutions including:

- Ceramic IR Heaters

- Band Heaters

- Tubular Heaters

- Cartridge Heaters

- Casting Heaters

- Air and Finned Heaters

Exporting to countries such as South Africa, Saudi Arabia, UK, and Sri Lanka, we are recognized globally for our commitment to quality, competitive pricing, and on-time deliveries.

FAQ – Ceramic IR Heater

Q1: What is a Ceramic IR Heater?

A Ceramic IR Heater is an infrared heating element made of ceramic that emits heat in the 2–10 micron range, ideal for efficient industrial heating.

Q2: How do Ceramic IR Heaters work?

They emit infrared radiation that is directly absorbed by objects and surfaces, providing efficient and uniform heating without relying on air as a medium.

Q3: What industries use Ceramic IR Heaters?

They are commonly used in plastics, packaging, food processing, textiles, electronics, and coating industries.

Q4: What are the benefits of Ceramic IR Heaters?

They offer quick heating, energy savings, longevity, and customizable designs, making them suitable for a wide range of applications.

Q5: Can Ceramic IR Heaters be customized?

Yes, heaters can be built in different lengths, diameters, wattages, and configurations to match the specific needs of any industrial process.